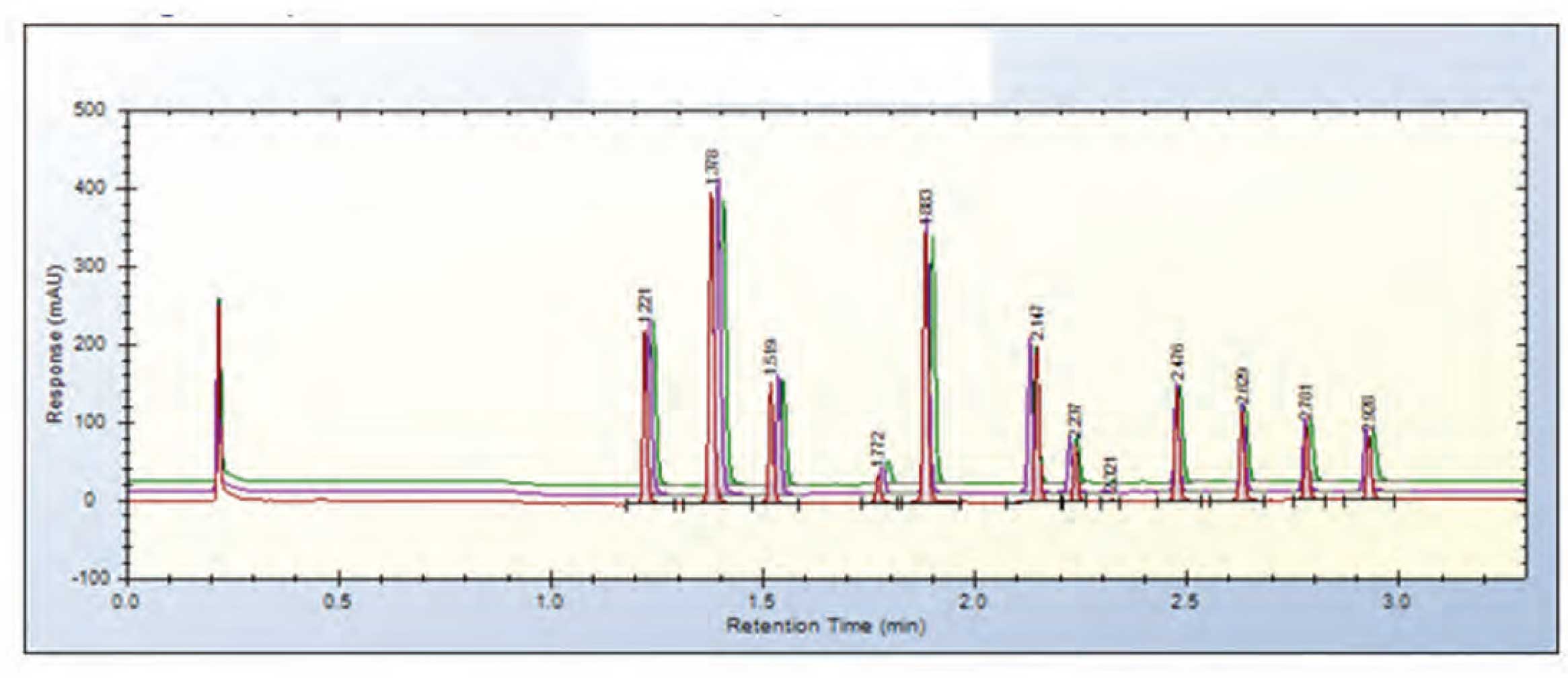

Last week (HPLC Solutions #72) we looked at how in-line degassers work. This week I’d like to look at an interesting case study related to the degasser that was contributed by a reader (WLT). The story goes like this: I am running a gradient from 0 to 95% B over 10 min on an HPLC system with low-pressure mixing (mixer before the pump). There is a significant amount of retention time drift (0.1-0.2 min, Figure 1) for all peaks. There is no trend of increasing or decreasing retention time from run to run. The service engineer has been in to check for leaks and even changed the multi-channel gradient valve but the problem has not been resolved.

Further tests were done to premix the mobile phase (50:50) and then use only line A or line B under isocratic conditions. Both channels showed repeatable retention times for 5 injections. But when I set the pump to mix 50% from line A and 50% from line B, the retention time drifts were again observed.

Figure 1

Figure 1

At this point, our suggestion was that there was something wrong with the gradient proportioning valve (although it had been replaced), or that there was an air leak somewhere in the system. Air leaks on the low-pressure side of the pump can be tricky to locate, because it is possible to have a small enough leak in a fitting connection that air can leak in, but liquid won’t leak out. The easiest thing to do is to tighten each low-pressure fitting a bit to see if it solves the problem. It is a good idea to tighten these fittings only with your fingers. Even though some designs look like they are intended for use with a tool, it is very easy to over-tighten such fittings. And as Murphy’s Law tells us, if you have a $5 plastic nut tightened into a $1000 mixing manifold… right, the threads in the manifold will strip. If you suspect a particular fitting of leaking and tightening doesn’t help, replace the fitting. These fittings are inexpensive and most brands are interchangeable, so you can change to another brand if you don’t like the design of the existing fitting.

Upon further communication with the reader, we found out that the root cause of the problem was the in-line degasser. A proportioning valve test was run for more details on this, as well as pressure tests on the pump and a pressure leak-down test (we’ll discuss these tests in future HPLC Solutions installments). All of these tests passed. Then it was discovered that the in-line vacuum degasser had failed. In this case, the vacuum pump had failed. When the vacuum pump and solenoid valve in the degasser were replaced, retention times returned to normal.

This is the first example I’ve seen of the results of a failed in-line degasser. The reader said that this is the third time a degasser had failed in his lab. If any of you have had degassers fail, I’d be interested in hearing your story, including the symptoms and how you corrected the problem.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com