In an earlier blog, we looked at the processes of sample filtration or centrifugation as a means of reducing or eliminating particulate matter from the injected sample. As I mentioned, I prefer centrifugation, because it is easy, inexpensive and effective. However, it is not perfect. This means that it is possible to get some particles injected along with the sample. And the sample is not the only source of particulate matter that may enter the HPLC column. Worn parts, especially the pump piston seals and the injection valve rotor seals, also can contribute to the particulate load of the system. Although it is pretty easy to minimize pump seal degradation by regular replacement on a 6- or 12-month cycle, injection valve seals seem to last forever – they can last 100,000–500,000 cycles or more. But when they fail, they can shed particles that can block your column.

Enter the In-Line Filter

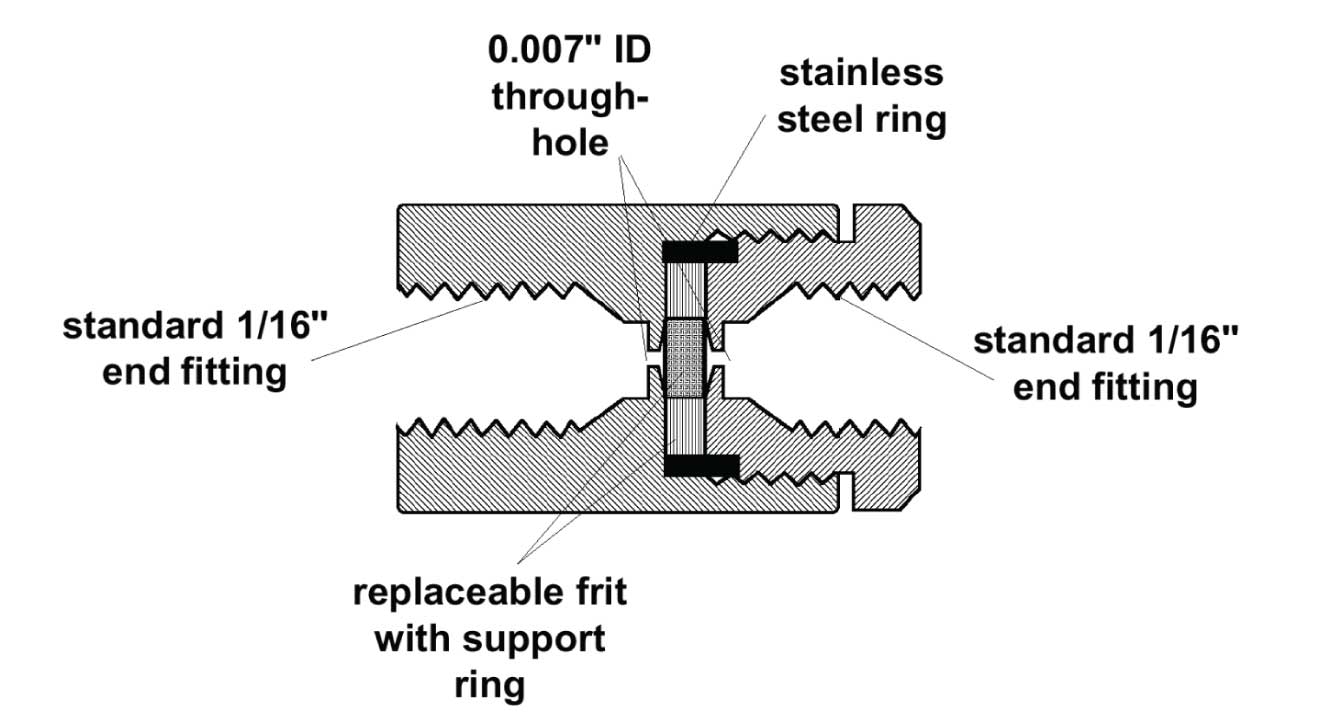

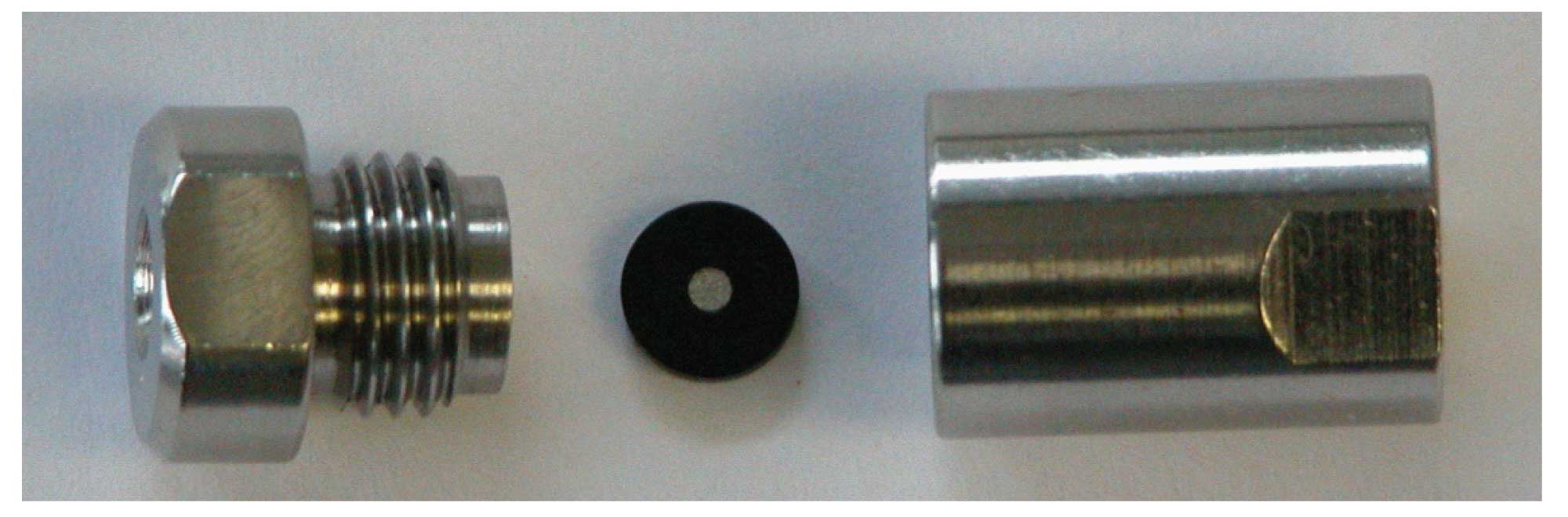

My favourite way to protect the column is to use an in-line filter. These filters come in a variety of formats, but they work in the same manner, and can be purchased from your favourite HPLC supplies dealer. My favourite is the design that uses a replaceable frit, such as in the sketch of Figure 1 or the photo in Figure 2. The frit typically is a stainless-steel frit mounted in a PEEK holder, as is shown for the black replaceable frit in Figure 2. A frit porosity of ≈0.5-µm is most popular, but if you are using a U-HPLC system, a porosity of ≈0.2-µm is a better choice, because these systems are more susceptible to problems with particles blocking the column. The nice thing about this design with a replaceable frit is that costs just a few dollars vs $15 or so for the unitized filters of Figure 3. The stainless-steel or PEEK filter body costs $50-$75 or so, but it is reusable, so it is a one-time investment.

I like to mount one of these in-line filters just downstream from the autosampler on every HPLC system, whether or not a guard column is used. I consider it the least expensive way to protect the column from particulate matter. In this position, it will also serve as a backup for the occasional sample that still contains suspended particulate matter after centrifuging, as discussed last week. If you are extra-cautious, you could mount one of these in-line filters just upstream from the autosampler to catch any bits of debris that might be released from a deteriorating pump seal, but I think this is a bit of overkill.

Figure 1 Figure 2

An alternative to the in-line filters shown in Figures 1 and 2 is the disposable filter shown in Figure 3. The black filter is a combination of a finger-tightened PEEK fitting and a 0.5-µm porosity in-line frit. At the bottom of Figure 3, you can see a tan version of one of these filters installed at the inlet to a column. These filters are quite convenient to use, and are replaced by a new one when they become blocked. The replacement cost, however, is 3-4 times as much as the design with the replaceable frit, so in the long run this choice is the more expensive of the two options. As we’ll see next week, the frit at the head of the guard column, if used, also acts as an in-line filter to protect the analytical column, but this is even more expensive than either of the two options discussed above.

Figure 3

Figure 3

In practice, the in-line filter is installed and ignored. Just keep an eye on the system pressure to determine when to replace the filter. For example, you might choose to replace the frit when the pressure increases by 50 bar (725 psi) or so. An additional advantage of the in-line filter is that replacement only takes about 5 min and you can be back in operation. If you had to replace the column or the frit at the head of the column, you would be out of business for an hour or more, and at a much higher cost.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his ongoing research with Lloyd Snyder, resulting in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com