PEEK (poly ether ether ketone) tubing has become a standard item in the operation of many HPLC systems. It is convenient, inexpensive, and easy to identify the internal diameter. However, some care needs to be taken to avoid problems associated with PEEK tubing.

Another advantage of PEEK is that it is easily cut to any desired length with a small guillotine-like cutter containing a razor blade. But be careful not to cut the tubing by slicing through it like you would with a pair of scissors – this can block the lumen of the tubing. Rather, pinch the cutter and rotate it around the tubing until a groove is cut all the way around the tubing. The tubing then can be snapped at the cut, leaving the lumen open. As with SS tubing, it is wise to run a few milliliters of solvent through the tubing to purge any particulate matter left from the cutting process. Just connect the up-stream end of the tubing to the HPLC system and turn on the pump for a minute or so.

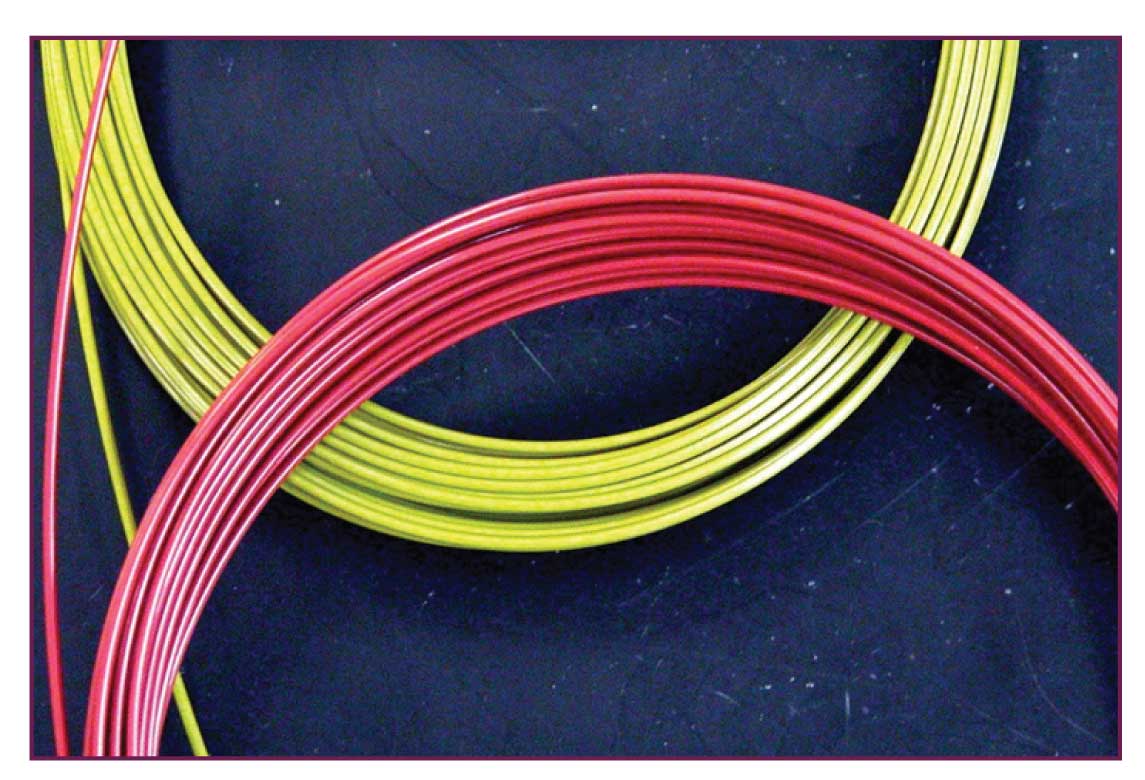

One thing I like about PEEK tubing is that it is easily identified. Most manufacturers colour-code the tubing, as is shown in Figure 1. The brand shown uses red to code the 0.005-in. (0.125-mm) and yellow for the 0.007-in. (0.175-mm) i.d. tubing. When I first saw this, I was worried about the colour leaching out and causing UV interferences. But our laboratory did extensive testing and did not find any evidence of problems with extracted pigments.

Figure 1

Figure 1

However, not all HPLC solvents are compatible with PEEK tubing. Aqueous buffers and salts are fine, as is acetonitrile (ACN), methanol (MeOH), and other alcohols. But tetrahydrofuran (THF) and the chlorinated solvents are not recommended for PEEK tubing. These solvents weaken the tubing and cause it to become brittle. I have found no evidence of UV interferences when these solvents are used, but be careful if you are using LC-MS. I have seen background problems created when THF was used with PEEK tubing in LC-MS applications, and it may be a problem with other detectors, as well. The best practice is to avoid the use of THF and chlorinated solvents when PEEK tubing is present.

I was a bit puzzled, though, when PEEK tubing instructions cautioned against the use of THF and chlorinated solvents, but I did not see similar warnings for PEEK injector rotors or other PEEK parts. So I asked an expert in PEEK chemistry, and learned that the solvent compatibility problem with PEEK is a result of the processing techniques. Tubing is extruded during manufacturing and needs some kind of a lubricant in the process. Rather than using plasticizers, which would be sure to contaminate an HPLC system, a small amount of the PEEK monomer is mixed into the polymer blend as a lubricant. It is this monomer that gets extracted out of the tubing and causes the brittleness and lower burst strengths. PEEK injector rotors and other machined or cast PEEK parts do not need the lubricant, so the monomer is not added, and a more solvent-stable product is achieved.

Speaking of burst strengths, most PEEK tubing can be used up to the upper pressure limits of conventional HPLC equipment (6000 psi = 400 bar), but cannot be used at higher pressures with U-HPLC type applications. The smaller internal diameters should have higher burst strengths because of the greater wall thickness, but it is wise to check the specific tubing specifications if you expect to expect to operate routinely at >4000 psi (275 bar) with PEEK tubing.

Another nice characteristic of PEEK tubing is that it can be connected with finger-tightened PEEK fittings. These allow tool-free assembly for convenient connections. Because the connection is less secure than a SS fitting on SS tubing, proper assembly is mandatory. With the pump off, push the tubing to the bottom of the fitting port, then tighten the nut. If the fitting leaks, turn the pump off, loosen the nut, reseat the tubing, and tighten the nut. Attempting to tighten the nut with the pump on can cause the connection to slip, creating leaks or internal voids. Also, although you can use PEEK fittings with SS tubing, don’t try the reverse. SS ferrules can pinch PEEK tubing closed or if over-tightened, can cut off the tip of the tubing.

Because of all the nice properties discussed above, I favour PEEK tubing for most reversed-phase HPLC applications at conventional pressures. I favour using SS tubing and fittings in places where I would like to make the connection and never worry about it again, such as between the pump and autosampler. However, whenever connections will be routinely changed, such as between the autosampler and column, and column and detector, PEEK is my first choice. If you are one of the few who haven’t tried it, you should give PEEK a try.