Q: I’m hoping you might be able to shed some light on an issue we’ve had with unknown peaks in nearly every method we run in our lab. I’ve been working at µg/mL levels for a cleaning method for one product, while a colleague has been working at similar levels for a high potency product dissolution. The sample matrices are completely different, as are the LC methods; the only common denominator was the low UV detection (210–220 nm).

I had major problems with extra peaks in my sample which I eventually traced back to the filters used for sample prep, and armed with this information, my colleague and I set about tackling filter studies for our respective methods. Both of us tried at least five different types of filter material, at 0.2 and 0.45 µm porosity and were still unable to solve the issue. Unfiltered samples appeared “cleaner” than any filtered samples. After another long hard think, and after testing all of the individual components of our respective methods (reagents, diluents, etc.) we realized that only filtered samples were the issue, and the commonality among all was the syringes.

I’m wondering if you’ve encountered issues with the syringes used to filter samples, and if so, do you have any recommendations for syringes that have low extractables? My diluent was 60% MeOH/buffer, while the dissolution samples are aqueous USP buffer, and the other methods tend to have >50% organic (usually MeOH or ACN) in sample matrix.

A: It is very frustrating when sample clean-up procedures end up being sample “dirty-up” ones! Contaminating residues can come from a variety of sources in the laboratory. At various times I’ve seen contamination from tubing, poor dishwashing practices, contaminated helium, and pH meters. Although I have not had specific problems with syringes, it is not a total surprise. Because of the inconvenience of cleaning and expense of inventory, most of us tend to use disposable syringes and sample filters.

Possible contamination of plastic products comes from the manufacturing process. For soft plastics, plasticizers are added to the plastic to make if have desirable properties. The worst offender in this is Tygon tubing, which has a large percentage of its total composition as plasticizers, generally one or more of the phthalates. The plasticizers leach out of the tubing over time and the tubing gets stiffer. The plasticizers also can contaminate the laboratory environment. I remember one episode in graduate school when a fellow student in an adjacent lab was trying to run a pesticide residue method by gas chromatography in which diethylhexyl phthalate interfered.

He found phthalates literally everywhere! Even a clean syringe filled with a sample of laboratory air gave a peak at the most sensitive settings. Fortunately, plasticizers are not used commonly in the harder plastics that are used for sample tubes, syringes and filter holders. These most commonly have polypropylene or high-density polyethylene parts. As you may know, plastic parts that are extruded or molded often require some kind of lubricant or “release” compound to prevent them from sticking to the fabrication dies. Any residue of these lubricants can, under the right circumstances, represents a potential interference.

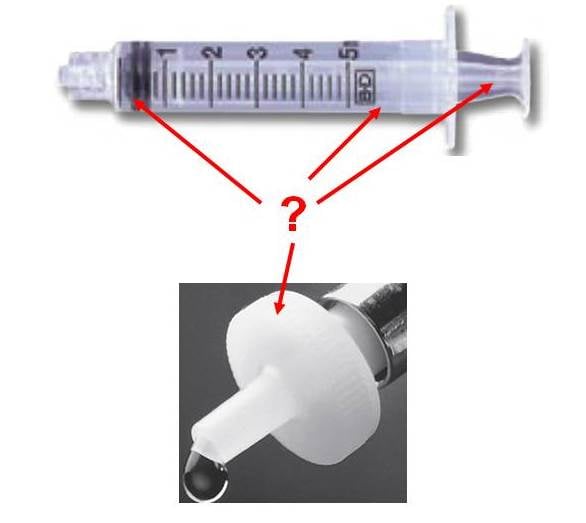

I would try to isolate the source of the contamination, then make a decision about how to correct the problem. I know of at least two different types of disposable syringes. There are the typical medical syringes that have a plastic barrel and plunger with a soft grey seal on the plunger portion. There also are syringes with fins molded into the plunger so the additional seal is not needed. I would separately rinse the surfaces of the syringe barrel and plunger with an organic solvent, such as MeOH or ACN. If the plunger uses the soft seal, take it off and rinse it separately. Devise a similar test to check the surfaces of disposable filter cartridges. This may require destroying a few cartridges so that you can wash the filter holder separately from the filter itself. Collect the various rinse solvents, concentrate them by evaporating part of the solvent, and inject them to see which contribute peaks.

Once you find the guilty party, you can decide what to do next. Should you use a stainless-steel filter holder and clean it between each use? Maybe change to a different brand or design of disposable syringe? Use glass syringes and clean them? Pre-rinse the syringe and/or filter with solvent to remove any residues?

Follow-up: After the first round of emails, I had a follow-up email indicating that the problem was isolated to the plungers of the syringes, and to my surprise, the problem syringes were those with integral fins to seal. Glass syringes had no residue and plastic syringes with integral fins to provide the seal on the plunger gave minimal problems. I suppose the finned design must require a different (or more) mold release than the non-finned design. Fortunately, the solution to the problem was pretty simple – just change to the syringes with the soft grey seal.

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com