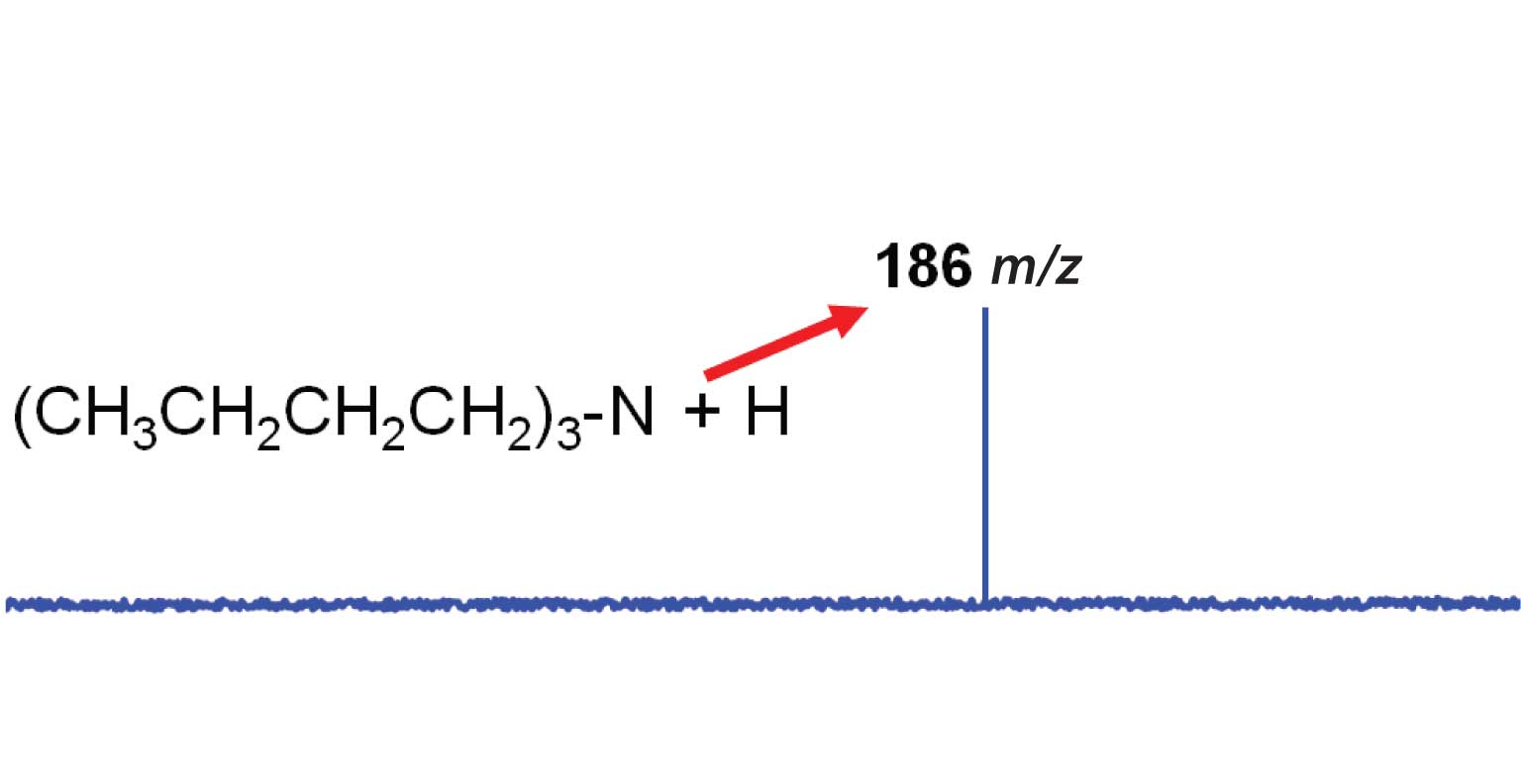

A reader recently sent me an email with this question: I run an LC-MS system and was recently tempted to try a recent published method using ion-pairing chromatography with 10 mM tributylamine (TBA).After the trial, I converted back to the regular reversed-phase system and have now been plagued by the wretched 186 m/z peak for over a week. I have flushed the system thoroughly and replaced the peak tubing to no effect.

I doubt from this experience that I will be trying ion pairing again and would have hoped the publications would have included a warning regarding this effect. Can you offer any advice on how to purge this contaminant from the system?

A: As you have discovered the hard way, one of the difficulties of MS detection is that the interface can have a strong memory for things that it has seen in the past. From your question, I assume that you are using mass spectrometric (MS) detection with the electrospray interface in the negative-ion mode for the TBA method. The positively charged TBA will act as an ion-pair reagent with negatively charged analytes. When you switch back to the positive-ion mode, any residual TBA in the system will appear as a background signal – in your case as the 186 m/z peak in the mass spectrum.

Figure 1

Figure 1

The residual TBA could be coming from anywhere in the system, so you’ll need to flush the entire HPLC system or replace some of the parts. I would start by removing the column and running directly from the autosampler into the detector (install a 1-m x 0.125 mm/0.005-in. i.d. piece of PEEK tubing as a restrictor between the autosampler and detector, if necessary). Monitor for the 186 m/z peak. If you are lucky, it will be gone when you remove the column. If this is the case, install a new column and resume operation. If the peak persists, you’ll need to flush the TBA from the system.

I would suggest flushing the entire HPLC system (including autosampler wash solvent lines) with 0.1% formic acid in water. First, replace the inexpensive and easy-to-replace items, such as the mobile phase reservoirs and inlet-line frits in the reservoirs. Flush the system to waste (not into the detector interface) – try running 25-50 mL of 0.1% formic acid through the system at 1-2 mL/min. Don’t forget to wash both the inject and load positions of the autosampler. Include 10 or more injection cycles with the maximum injection volume and syringe flushing. I would also perform a routine cleaning of the MS interface, using normal procedures. A rinse of the various parts in 0.1% formic acid might help to remove the TBA here, too. Once the flushing has been completed, hook up the system again (still no column) and I think you’ll find that it will be serviceable. If you still have the residual 186 m/z peak, you may need to dig deeper and clean the first quadrupole (Q1) and any parts between the interface and Q1.

I consulted my good friend Fred Klink at Mass Spec Training for additional advice. Fred’s response, “As a general rule, I never want to introduce any amine-containing reagent into an LC-MS electrospray system which will be used for positive ion. Not only do you see the spurious peak resulting from the reagent but, more seriously, the presence of the amine is probably causing ion suppression of your analyte.” This reminds me of my days in the software business. We occasionally had someone call in, upset because the software crashed. On further questioning, the crash only occurred when the ctrl-alt-;-& key combination was pressed – an extremely unlikely occurrence in normal operation. We referred to this as a “DDT bug” – Don’t Do That. So, as Fred so sagely advised, DDT!

This blog article series is produced in collaboration with John Dolan, best known as one of the world’s foremost HPLC troubleshooting authorities. He is also known for his research with Lloyd Snyder, which resulted in more than 100 technical publications and three books. If you have any questions about this article send them to TechTips@sepscience.com